H&D2 Ammo Box Shuttles

February 14, 2005 | 00:00

Companies: #ati #corsair #creative #shuttle #western-digital

The handle I chose is spring-loaded so it will lay flat when not being used. It will be attached to the case using pop rivets.

A centreline was measured and drawn along the top of the case lid.

Using the handle as a template, its mounting holes were marked out. Note that the holes are not along the centreline but the handle pivot is - this improves the balance when carrying.

Similarly the mounting holes for the catch were scribed and..

...then all the holes were drilled.

A quick mock-up with the taped on edging, handle, catch and a test text label was made to check that the desired effect was being achieved.

Although the two Shuttles would have a somewhat similar appearance when finished, I did want each to be unique. To this end, I decided to cover one of them with a checker plate finish. This is an embossed, metalised sticky-backed sheet on a roll which can be cut with scissors or a sharp knife. When stuck in place it looks and feels like the real thing.

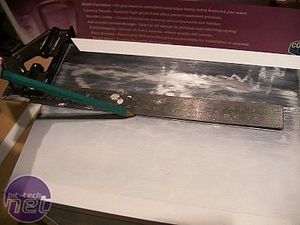

Another mock-up to check the effect of the checker plate with the plastic edging.

Using the checker plate presented a problem: it covered all the ventilation holes in the case sleeve. Not a good idea given the high powered heat producing components inside these babies. Fortunately, a pop rivet was just the right size to puncture the plate to reopen the holes, all several thousand of them!

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.